This post is an updated version of an older blog post from 2019.

A perfect storm has been brewing in the global steel market. Strong demand has collided with supply shortages, causing the price of steel to reach an all-time high and inventory levels to plummet.

Like other sectors of the economy, the propane industry is feeling the impact. Marketers have reported that a 500-gallon tank that cost $800 two years ago now costs approximately $1,600. Not only have tank prices doubled, but according to feedback collected by NPGA, tank orders placed today likely won’t even be delivered until early 2022.

How Can We Combat High Costs and Low Inventory?

You have little control over the factors that influence tank prices and inventory, so why waste your resources trying to fight them? The best way to increase your bottom line is to change what you can control – your costs.

As some propane marketers began deploying more tank monitors, they realized that instead of purchasing a new 500 or 1,000 gallon tank for high-volume users, they could begin to control their own supply and demand with greater visibility into those tank levels.

By using a tank monitor on high-volume accounts, these propane marketers have been able to avoid spending thousands of dollars on an unnecessary second tank.

While the Cost of Tanks Goes Up, the Cost of Monitors Goes Down

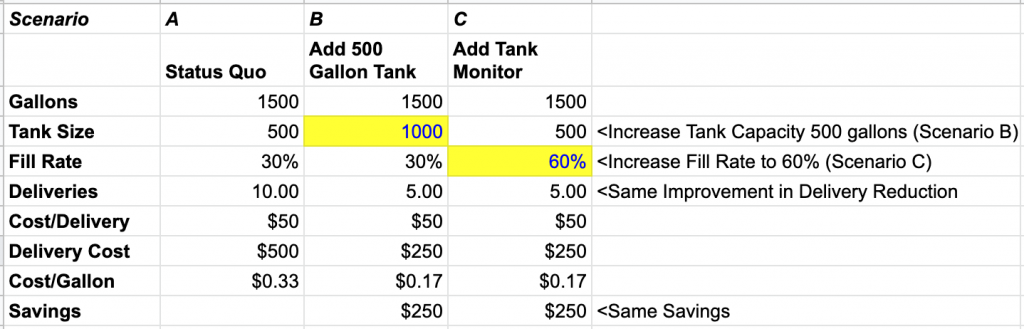

So how does the math work out? Is it really less expensive to monitor high-usage accounts instead of adding a second tank? Consider the example below:

Let’s say you deliver 1,500 gallons/year to a customer with a 500-gallon tank. Because they are a high-volume user, you top them off frequently which makes your fill rate approximately 30%. This means you’re making 10 deliveries/year. By adding another 500-gallon tank to this account (Scenario B) you can cut the number of deliveries to 5/year. If your cost/delivery is $50, this equates to a savings of $250/year.

However, instead of adding a new tank to reduce the number of deliveries, you can achieve the same thing with a much smaller investment by adding a monitor to the existing tank. A monitor enables you to hone in on tank level, and set an alert to deliver when the customer’s tank is at 20% or less. With an improved fill-rate of 60%, you will reduce deliveries to 5/year and achieve the same $250 savings/year (Scenario C).

Tank vs Monitor: Consider the Investment

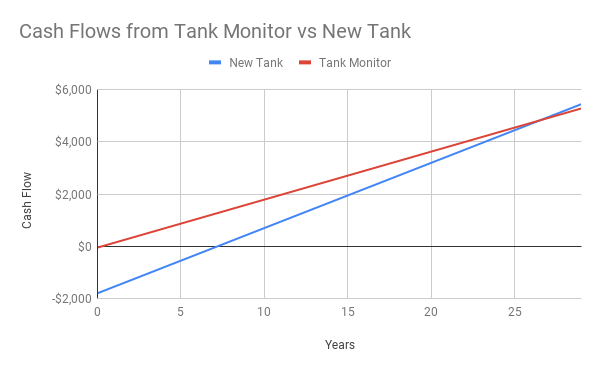

As mentioned, a new 500-gallon tank will run you $1,600, plus an additional $200 for the installation fee. That’s a hefty $1,800 investment. Compare that to renting a tank monitor for $66 per year, and it would take over 27 years of monitoring an account before you even make up for the initial investment in a new tank. That break-even point only increases if you decide to purchase the tank monitor outright.

A tank monitor also helps increase profit margins in other ways:

- Fewer truck rolls due to a more efficient 60% fill rate

- Stop paying drivers overtime for unnecessary, one-off trips with improved routing

- Prevent costly run-outs and urgent delivery requests with real-time tank level data

- Charge customers for tank monitoring services

Choose the Solution that Delivers the Best Return on Investment

Generac takes the work out of tank monitoring for you with software that helps you drop more gallons with fewer deliveries, tools to grow a more profitable business, and a team that helps you reach your goals. Get in touch to learn how Generac help you start saving.

Shop

Shop